This model is suitable for low and medium hardness materials, such as chemical engineering, dyes, additives, food, feed, medicine, non-me

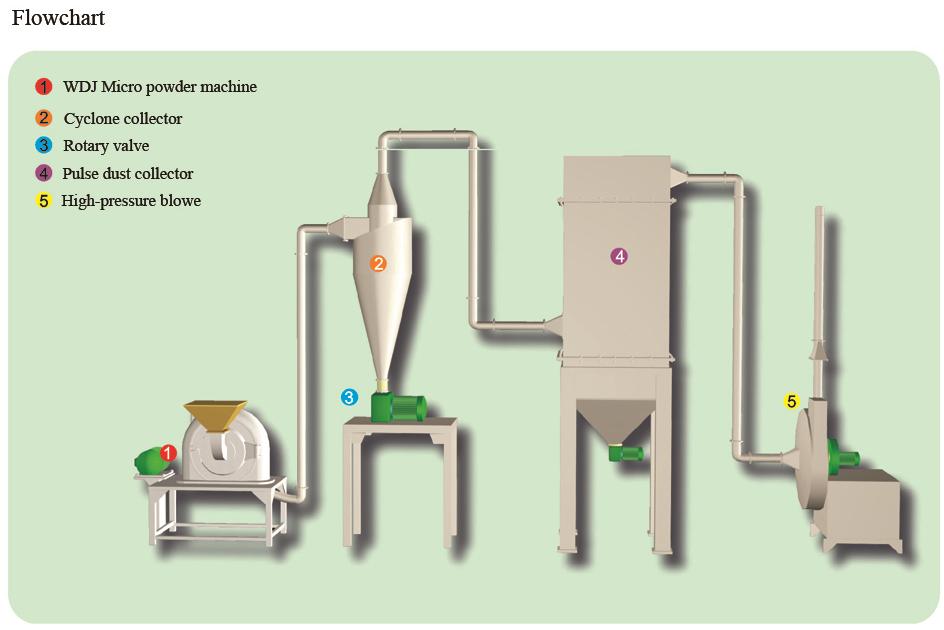

The machine is mainly composed of the rack, machine door, turbine, spindle and screen. The turbine rotates at high speed to absorb a large amount of air and material. The material and the air flow rotate with the rotating turbine. Turbine and sieve ring on the grinding block consist compact-structured grinding area. The material frict closely in swirling flow and strongly impact to the inner edge of the turbine blade, and re-grind in the gap between the blade and the grinding block. The qualified powder is filtered from the screen and be discharged from the bottom chamber. During the process, the massive air sucked by the turbine has the function of cooling, milling and delivering the material. The powder fineness depends on the material nature and screen size. The bearing is equipped with a unique labyrinth seal, which effectively prevents the dust and prolongs the service life of the bearing. The door is equipped with two O-shaped rubber sealing ring, no dust pollution.

① High efficiency because of the obvious particle separation and a certain amount of material.

② The finished powder is filtered from the screen.

③ Increase the output by the turbine-shaped rotor. The clearing is very simple. Only need to open the machine door and remove the guide blades.

④ This machine has the advantages of sound impact structure, small size, low consumption, high efficiency, stable transmission, low noise, reliable sealing, good cooling, easy maintenance and so on.