This machine is suitable for grinding normal materials, such as Kaolin, Limestone, Calcite, Talcum, Graphite etc. uninflammable and unexplosive material, whose humidit is less than 8%, morse hardness is lower than Grade 6. It is the ideal processing machine for non-me

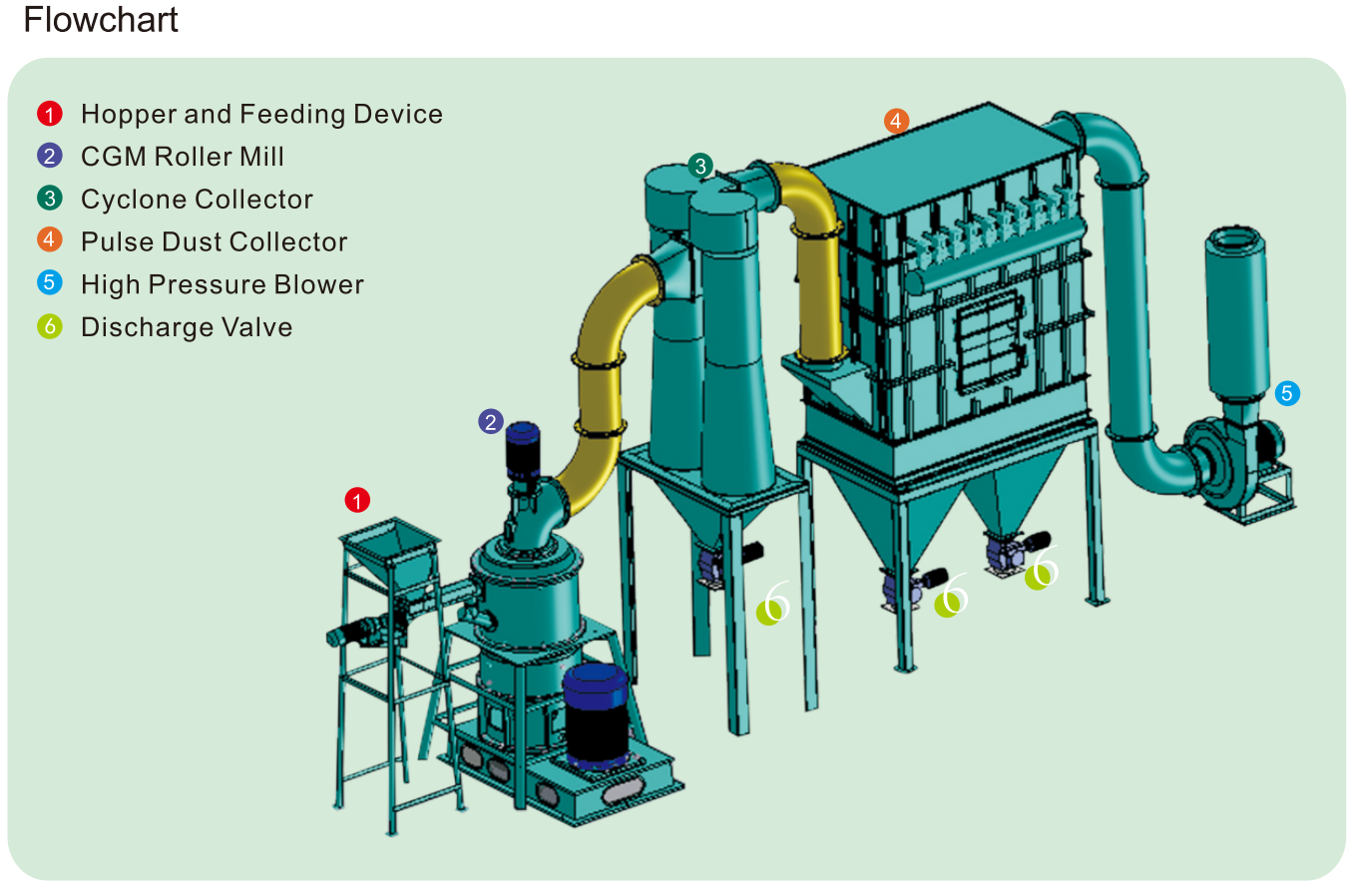

Ultrafine rolling mill drives the spindle by the transmission device. And the grinding wheel is on the auxiliary shaft, while auxiliary shaft is on the rotor shelf and the rotor shelf connects with the top of spindle. The auxiliary rotate with the rotation of the spindle. The grinding wheel on the auxiliary rotate around the spindle, and at the same time, the grinding wheel also rotate with the rotation of it's own auxiliary shaft. The grinding wheel generate the strong centrifugal force because of it's revolution and rotation, and enter into the comminution area which consist of grinding wheel and the fixed knife, and be pulverized by the strong extrusion and grinding effect. The grinded powder fall on the throw tray. The throw tray rotates with the main shaft. It throws the powder into the ring between the stator and the body, and is subjected to system negative pressure to rise along the diverter ring to the upper grading chamber for grading. The qualified fine powder enters the collection system through the grading wheel, and the coarse material falls into the comminuting chamber along the inner wall of the diversion ring and is crushed again.

The grading motor drives the grading wheel to rotate, forming a graded effect on the powder. The size of the finished product can be adjusted by the speed of the grading wheel. The coarse particles that do not meet the requirements are thrown by the blades toward the outer wall and fall into the grinding chamber to continue grinding. The particles that meet the requirements pass through the leaves and form a gas-solid two-phase flow, which is sucked into the cyclone collector, and the airflow and powder After the particles are gas-solid separated, the powder particles are collected.

① Compared to Raymond and jet mill, it's production efficiency is twice higher while the power is same. The grinding pressure is 30~40 % higher under the function of high-pressure centrifugal force.

② High yield: For calcium carbonat, the particle size is 10μm and the yield can reach at least 1 t/h.③Fine index of product fineness: D97=3~35μm, could reach the fineness index of fluidized bed counter jet mill.

④ Equipped with the frequency converter of sorting wheel, could adjust the fineness without stopping the machine. Also, all the fine powder is environment-friendly and recyclable.

⑤ The erection is convenient and no need of big civil engineering. Could runs at once after the installation.