The technical index reaches the level of similar imported machine, can replace the imported equipment.

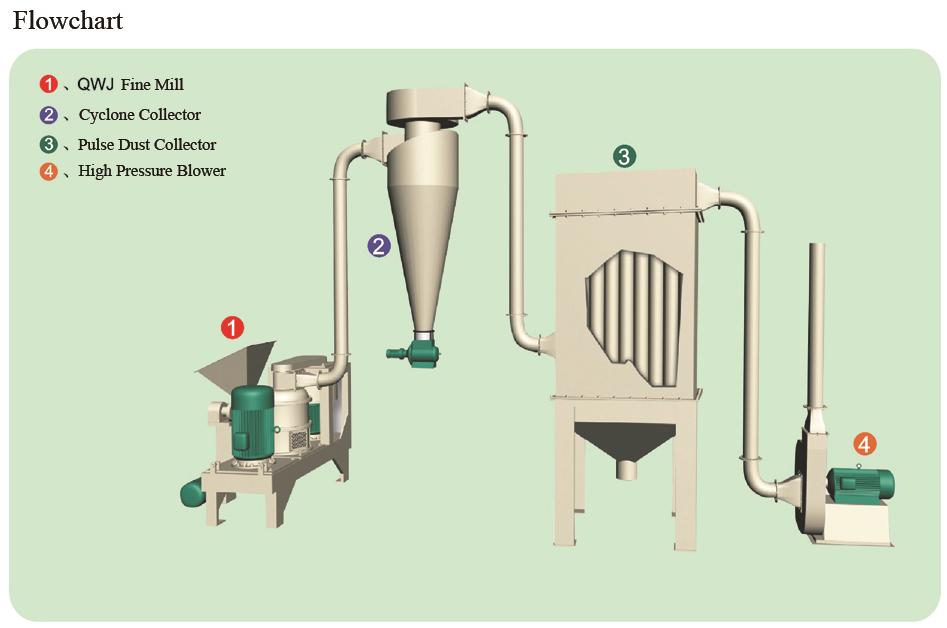

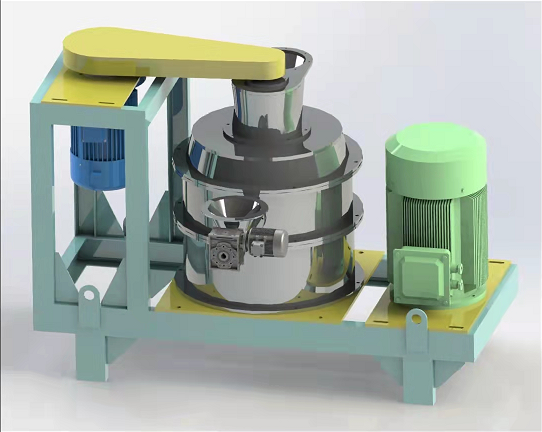

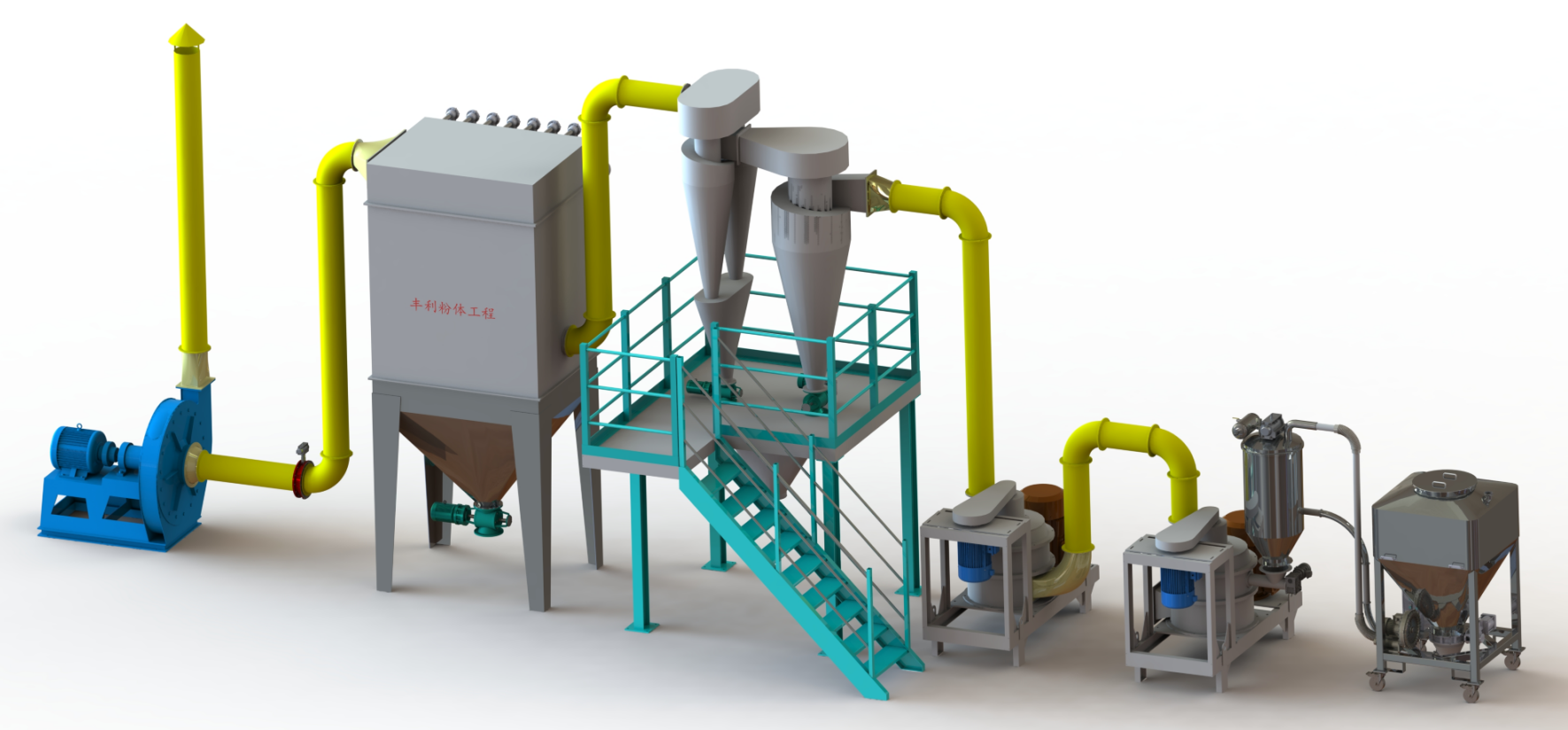

The machine cavity is cylindrical, which is divided into two parts by a ring-type: the lower part is air intake chamber, and the upper part is divided into milling room and classing room by the sorting ring. The material is grinded into fine powder and be sent to the classifying room. The classifying room can separate the qualified powder from the unqualified powder. The qualified powder is sucked out through the pipe and collected by the cyclone collector. The unqualified powder comes back the milling room and be re-grinded through the inner wall of sorting ring, until qualified.

① This machine is a vertical reflective grinder. There is classifying device in the milling room. The grinded powder is collected by the classifying device because of the wind power. The classifying device takes the place of the general grinder screen, has the dual functions of milling and classifying. High milling efficiency.

② There are a control valve of air flow rate and a stepless speed adjustor of sorting wheel in the machine. And can adjust the powder fineness when the machine runs. The particle size is evenly and can reach 10~15μm.

③ With the function of cooling. The temperature increase slowly when milling, is much more suitable for heat sensitive and fiber material. The powder is evenly.

④ High productivity with easy operation, maintenance and clearing.

⑤Adopt the new narrow V-belt, has the advantage of large transmission power, Stable operation (running balance), little vibration, low noise.