This machine is suitable for grinding normal materials, such as Kaolin, Limestone, Calcite, Talcum, Graphite etc. uninflammable and unexplosive material, whose humidit is less than 8%, morse hardness is lower than Grade 6. It is suitable for super fine grinding of wood chips and fiber materials.

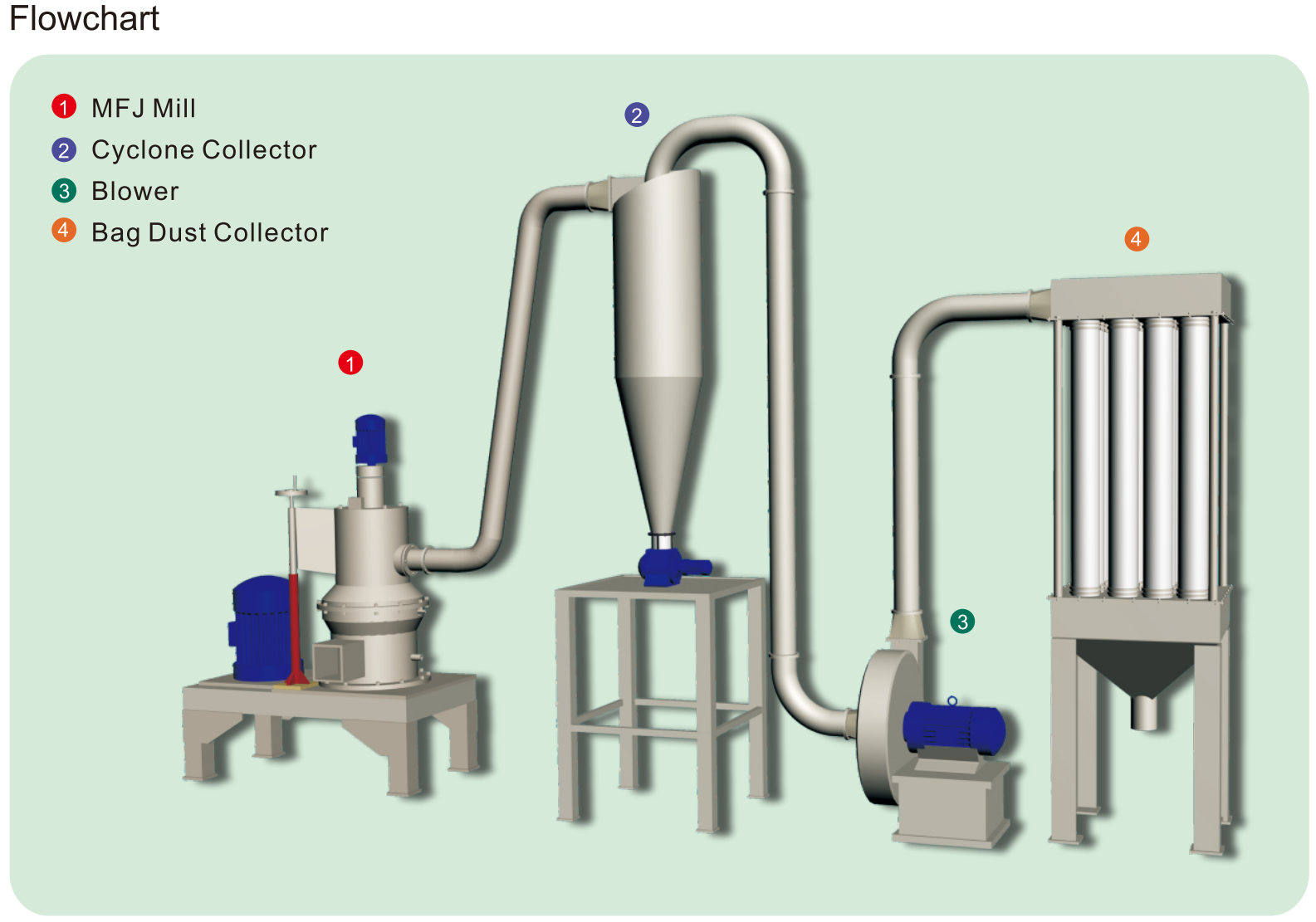

The MFJ machine drives the spindle through the transmission device.There are 4 - 6 pieces of auxiliary shaft on the rotor shelf, and the shelf head is connected with the spindle. The grinding wheel and swing arm device, which are on the auxiliary shaft consist of the swinging pivot. The grinding wheel generate the strong centrifugal force because of it's revolution and rotation, and enter into the comminution area which consist of grinding wheel and the fixed knife, and be pulverized by the strong extrusion and grinding effect. There is scraper system under the rotor shelf, which is under the grinding wheel device. The scraper take the meterial into in comminution while rotate with the grinding wheel simultaneously. Then comes the Bedding la

The classifier motor drives the sorting wheel to rotate and grind the powder.

Because the powder is grinded all the time in the comminution chamber and the temperature raised quickly. So there is equipped with the water cooling jacket outside the chamber to cool down the inner temperature of the comminution chamber.

① Compared to other mill, it's production efficiency is 20~30% higher while the power is same. The grinding pressure is 30~40% higher under the function of high-pressure centrifugal force.

② Energy Conservation: For the same yield and fineness, the consumption to grind the sawdust material is only one third of the airflow mill.

③ Fine particle size: The smallest size can reach 400~600 mesh for the sawdust material.

④ With the cooling function, and low temperature when runs. It is suitable for the heat-sensitive and fiber materials.